Today’s data center and telecommunications environments heavily depend on the foundations of the optical network communicating, transmitting, and protecting the data upon which your business relies. So what makes your optical network different to your competitor’s network? How can the design and performance of your data / telecom environment contribute more to the bottom-line, while at the same time be mindful of reliability and uptime. It’s achievable with Fiberstore Ultra High Density Solutions, industry engineered pre-terminated optical cabling systems that take your data/telecommunications environments beyond the next level.

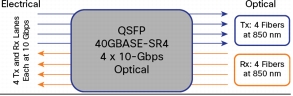

The fiber system has a higher and higher demand on fiber optic connectors with changes from single mode fiber to multimode fiber, from 10G to 40G, 100G. Ethernet transmission of 40G and 100G also becomes the developing trend in data center cabling system. Traditional connectors are more and more difficult to achieve Multi-Fiber and High-performance. According to the International standard port in the Ethernet transmission of 40G and 100G.

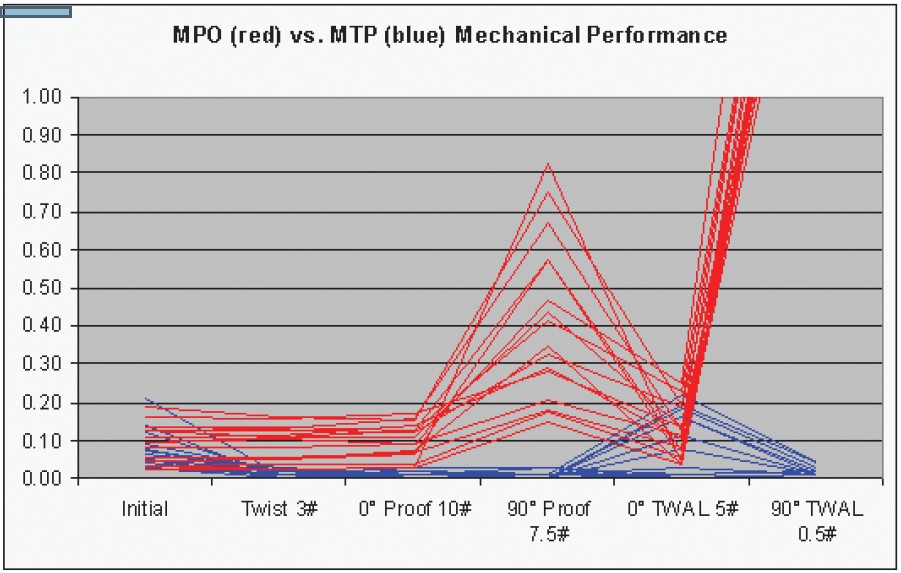

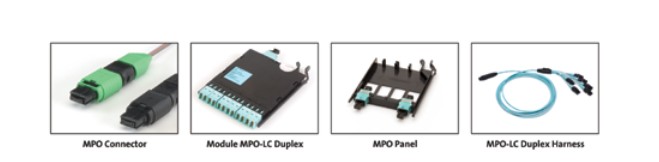

FS develops a high density MTP/MPO cabling solution with its constant innovation in the field. The MTP MPO is a standard mini, high-density connector, equipped with Multi-core ribbon fiber, which makes the connection stable and reliable. The connection and testing of high density connector with ribbon cable are finished in factory, so that it can be plugged and played with the equipments on site directly, and support the rapid deployment at users’ data center, which makes MTP/MPO cabling system become ideal solution with growing demands on high-capacity cabling data center. Simple installation, fast contruction, compact design, high precision, plugs and play, etc.

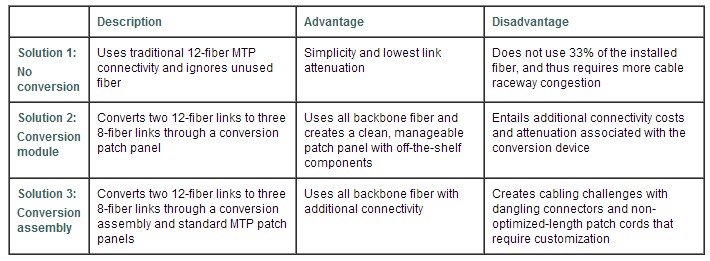

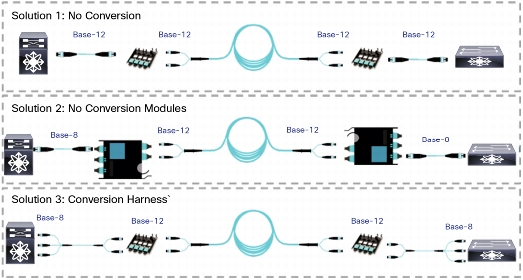

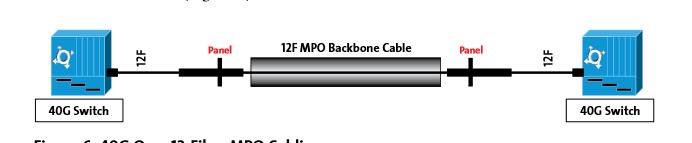

FS offers a wide range of high density patch panels and fiber enclosures that will help free up rack space. Our 24-fiber MTP cabling systems provide at least double the density in enclosures and allow for fewer cable pathways than legacy 12-fiber cabling. And high-capacity cable management solutions make it easy to route additional networks while improving overhead space and access. Now the following is the introduce of the High Density MTP/MPO cassettes.

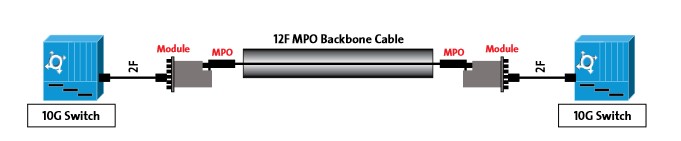

The High Density MTP/MPO cassette system is compatible with a 1U 5 slot modular chassis scaling up to 120 discrete fibres in a 1U space. High Density MTP MPO Cassette provide secure transition between MTP/MPO and LC or SC discreet connectors. They are used to interconnect MTP/MPO backbones with LC or SC patching. Modular systems allow for rapid deployment of high density data center infrastructure as well as improved troubleshooting and reconfiguration during moves, adds and changes.

With a rear bottom tray that slides inward for easy access to the connectivity while the enclosures are stacked on top of each other, FS offers best in class accessibility compared to any other high-density fiber enclosure on the market. In the out position, the rear tray acts as a cable partition between stacked enclosures. Low-Loss Plug and Play Modules are also easily inserted or removed from either the front or rear of the enclosure and the visually appealing easy-open magnetic door eliminates harmful pinch points and offers high-visibility drop-down labeling.

Available in OM4 multimode and singlemode, the ultra-slim LC-to-MTP Low-Loss Plug and Play modules offer the industry’s lowest loss performance of 0.35dB for flexible fiber channels. Fully ready to support 40 and 100 gigabit applications, FS low-loss 0.2dB MTP pass-through adapters are available in 2, 4 and 6-port designs and they are offered in both aligned and opposed key orientation to accommodate all polarity methods. Unlike other fiber solutions on the market, FS also supports 12-fiber LC pass-through adapter plates for current 10 gigabit Ethernet or Fibre Channel SAN applications.

“As today’s high-density data centers migrate from 10 to 40 and 100 gigabit speeds, they require low-loss fiber connectivity to support multiple mated connections for flexible patching options over a wide range of distances and configurations while remaining within link loss budgets. At the same time, these connections need to be easily accessed and managed to quickly and effectively make changes,” explains Charlie Maynard, Fiber Optic Product Manager at Siemon’s global headquarters. “With superior best-in-class features, our new Ultra High Density Fiber System is uniquely positioned to overcome current and future fiber connectivity challenges.”