The physical level of cable management covers the actual cabling itself. Using physical cable managmement systems ensures that you keep your cables in a safe, neat layout.

Because fiber optic cabling is brittle, the glass fibers within the cables can bend only so far. If they get twisted into a knot or around a tight corner, they snap like glass. Broken fiber optic cable is hard to identify, because sometimes the light still gets through just enough to work. Think of a garden hose with a kink: Some water will gets through, but in spurts versus a steady flow of water. When a fiber optic cable sometimes lets light through and sometimes doesn’t, you end up with a flaky connection that can cause all kinds of issues out on your SAN. With orderly cable placement, if a cable does ge broken somehow, it’s easier to replace it if you don’t have to fight with that giant day-glow orange spaghetti under the floor.

A good cable management system usually comes in the form of a rack or some types of 19” rackmount panels that securely hold the cabling. The rack or panels have tracks where the cables run next to or inside your equipment racks so that they can easily yet safely flow between one component and another.

Some of these systems come with patch panels, which have rows of fiber optic ports on the front that allow you to connect the cables that come out of components or other patch panels. Patch panels give you a prelabeled system you can use to interconnect your components or other patch panels. Patch panels give you a prelabeled system you can use to interconnect your components without having to run new cabling every time you want to add or change something in your SAN layout. With patch panels, you hook up all the connections on each of your components to the ports on the panels. You run the fiber-optic cables from your server’ HBAs to a patch panel as well. All cabling is run en masse to the backs of these centrally located panels. When you want to connect components to your servers, you use short fiber optic cables (patches,) usually less than 3 meters long (abount 10 feet), to patch the ports from your arrays to the ports of your swiches to the ports for your HBAs.

Figure 1 shows how a typical patch panel solution connects your SAN components without requring you to lift a floor tile or roll a spoll of cable across the floor. Another benefit of using a patch panel is that running fiber-optic cable on a one-by-one basis can be very expensive. In a fewer times electricians have to come in to put in more cables, the better. Running a group of cables in one shot from the very beginning is much cheaper and faster than doing it one by one later.

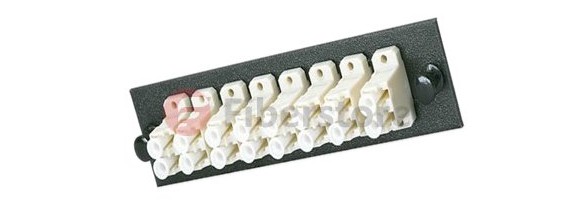

Patch panel systems also make things very flexible. Now that you have all the endpoints of your SAN components in one place, you can easily control what talks to what by using the short, easy-to-manage patch cables. Following is the diiferent ports example of fiber optic patch panel, there are 12 port fiber patch panel, 16 port patch panel, 24 port patch panel.

12 port fiber patch panel loaded with a 12 port Multimode LC Adapter plate and a fiber optic splice tray. Also included is a pack of 60mm splice sleeves and a 12 pack of Multimode 62.5/125µm LC Fiber Optic Pigtails. This Pre-Loaded 1U Patch Panel comes with three adapter plates for easy expansion without the need to purchase more panels. Any unused adapter plate slots are covered with a blank plate to protect the insides of the patch panel.

16 port patch panel provides efficient and easy management of fiber optic cables in the rack or cabinet. Pre-loaded, feed-thru duplex multimode connectors are mounted on a 16-gauge, cold rolled, black powder coated steel panel.

With this High Density 24 port patch panel, you can easily make one rack unit support your 10GB or higher applications. They allow you to quickly add new devices to your system without having to manually install or reconfigure other devices. The fiber is routed and connected on the inside of the cassette. There is no cutting, polishing, or terminating. These patch panels are perfect when you have high fiber count installations.

Fiberstore offers a complete range of fiber optic patch panel, loaded Patch Panel Kits with pigtails from 6 ports to 36 ports in all connector types LC, LC APC, SC, SC APC, FC, FC APC, and ST and up to 72 ports with LC or LC APC. 2U Patch Panel Kits with pigtails from 6 ports to 72 ports in all connector types LC, LC APC, SC, SC APC, FC, FC APC, and ST and up to 144 ports with LC or LC APC.