Optical fiber has brought changes to the telecommunication industry throughout the world, therefore, it is essential for us to learn some skills necessary for working with optical fiber. It is known to all that when adopting or splicing a fiber, clean ends should be assured. And fiber optic cleaving serves as one of the basic and important steps to ensure fiber ends clean and smooth, thus the significance of cleaving process cannot be underestimated. This article aims at providing some basic knowledge about cleaving and introducing common tools for cleaving.

Fiber optic cleaving is one of the several processes in the preparation for a fiber splice operation. The purpose of cleaving is to prepare the end of the fiber so that it makes a very nearly perfect right angle with the body of the fiber and that this end face is nearly perfectly smooth. With a well-performed cleaving operation, a clean and flat endface was created perpendicular to the length of the fiber, with no protruding glass on either end. Besides it can also help to achieve a successful low loss splice of an optical fiber.

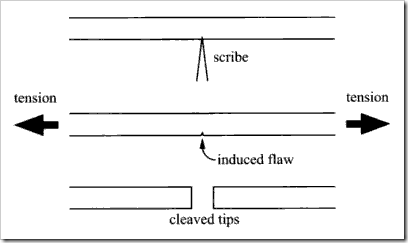

A general strategy involved in the technique of fiber optic cleaving is known as the scribe-and-tension or scribe-and-break strategy. With the use of cutting tool made from materials such as diamond, sapphire or tungsten carbide, this process involves the introduction of a crack in the fiber, then followed by the application of tensile stress in the vicinity of the crack.

However, the specific implementations of the cleaving can be various thus lead to cleaves of different qualities. Some implementations may apply the tensile force uniformly across the cross section of the fiber while others might bend the fiber around a curved surface, causing excessive tensile stress on the outside of the bend. Besides, the crack in the fiber may also be generated in different ways: the crack may be introduced at a single point on the circumference or it may be generated all along the circumference of the fiber prior to the application of the tensile force. The circumferential introduction of the crack often allows fibers of considerably large diameters to be cleaved while maintaining high quality of the cleave.

Basically, there are two kinds of cleaving tools which are commonly employed in fiber optic cleaving: pen-shaped scribe and mechanical cleaver.

Pen-shaped scribe looks like a ballpoint pen, but with a small wedge tip made of diamond or other hard material that is used to scratch the fiber manually. After scratching the fiber, the operator pulls the fiber to break it. In essence, both the scribing and breaking process are under manual control, making it more dependent on operator technique and less predictable as they require operators to exert force manually for breaking the fiber. So, an experienced operator is required to produce good cleaves.

And the other tool is mechanical cleaver, which is widely used because it can produce nicer and more repeatable cleaves. This cleaver is much easier to use thus the specific training is not essential. Just clamp the fiber in the correct position into the cleaver. Then, a force is applied and the fiber gives a nice break at the scribe.

Since fiber splicing requires mating two fiber ends together, any defect of the ends would impact the performance of fiber splicing. So in order to achieve good fiber optic splices or terminations, it is extremely important to cleave the fiber properly. And a good cleaver can help better finish the whole cleaving process.