When designing and implementing their high-density networks, most data center managers and operators are inclined to options which are more sustainable and environmentally sound. They always expect systems to provide high performance and reliability for maximum network uptime over the long term. Since the demand for higher bandwidth and flexibility for future growth never ending, network administrators now are seeking to the network’s physical media infrastructure to achieve these goals. And the growing adoption of pre-terminated cabling system serves as one of the trend, that is what we will explain in this article.

Then what the pre-terminated cabling system refers to and how it differs from field terminated one? In fact, pre-terminated cables go through the same procedures as field terminated cables, but these steps are taken at the manufacturer’s facility or cable assembly house and delivered to the job site with the connectors already terminated, properly polished, and the entire cable assembly tested on either both or one end. Which helps to eliminate the necessity for on-site field termination. Compared with field terminated cabling products, pre-terminated fiber cable assemblies are more convenient and flexible. They are most suited for network installations that are planned well in advance, taking into account both current and future requirements.

Installing and connecting your cable infrastructure in the data center consists of various labor intensive tasks. And manual field terminations, troubleshooting, and error corrections also extended deployment times, higher installation costs and increased downtime. However, with the deployment of pre-terminated cabling system, you are supposed to benefit from it with the following aspects:

- Installation time and costs are substantially reduced.

- Material reductions of 50 percent or more are typical when using pre-terminated systems rather than traditional systems.

- Network performance and reliability are assured due to in-factory testing and validation of components.

- Modular components at the physical layer are reusable. They can be disassembled and repurposed to accommodate moves, adds and changes, which provides greater flexibility and portability, as well as a clear migration path to support new technologies and applications as an organization grows and requirements change and evolve.

- Pre-terminated installations are more precisely planned, which results in a neater, cleaner appearance, as well as faster and easier cable management, maintenance and troubleshooting.

It is undeniable that pre-terminated fiber cabling system indeed offers a constructive and ideal solution to data center management and maintenance. Here in this part, we will further introduce some most commonly employed pre-terminated fiber cables, including fiber patch cables, fiber optic pigtails and MTP/MPO pre-terminated cables.

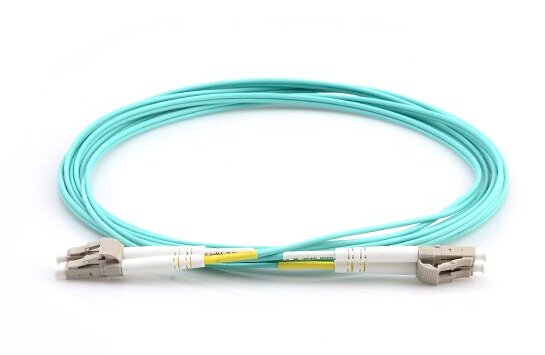

As one of the most used components in fiber optic networks, fiber patch cables help to ensure a reliable temporary fiber optic interconnection. There exists a wide range of fiber patch cables on the market, available in single-mode and multimode versions with PVC, LSZH, OFNP or armored jacket. And connection type options involve LC, FC, SC, ST, MU, MTRJ and E2000 pre-terminated in duplex or simplex fiber. Fiber patch cables are suitable for all kinds of fiber optic connectivity applications.

Fiber optic pigtail, which is a fiber optic cable of a specified length, has only one end terminated with the appropriate connector style and an open unterminated end. A pigtail can be fusion spliced onto a pre-terminated fiber optic cable assembly to extend the cable distance or onto field-terminated cables to provide the connectorized end. Pigtails do not need the same configuration or connector style as the opposite end. Keep in mind that when installing pigtails, you must be trained and will need additional equipment, such as a fusion splicer and fusion splice trays.

Pre-terminated with high-quality and low loss MTP/MPO connectors, this kind of cable can meet the high-speed, high-density, and wide bandwidth demands of the current and future network. Basically, both MTP/MPO trunk cables and MTP/MPO harness cables are classified into this category. They are available in any fiber mode (single-mode and multimode) and a full range of length options.

Pre-termination cabling is not just a popular trend, it is an increasingly popular way of delivering a project in a more timely and cost effective manner. Which on the whole can provide benefits for all sizes of project.