In data centers, we run all enterprise network equipment (server, storage, network switch, etc.) into the server rack. And various wires such as fiber optic cables, Ca5e/6 Ethernet cables and power cords are spreading all over the floor. It’s rather a disaster to see all these cables tangling together without knowing which ends they are tracing to, which is inconvenient for operators to implement troubleshooting. Besides, interwined wires also cause cooling problem, crosstalk and interference, which causes performance issues. Fragile fibers under neglected management will easily break. All these reasons confirmed the necessity of proper cable management. So how to manage cables in server rack?

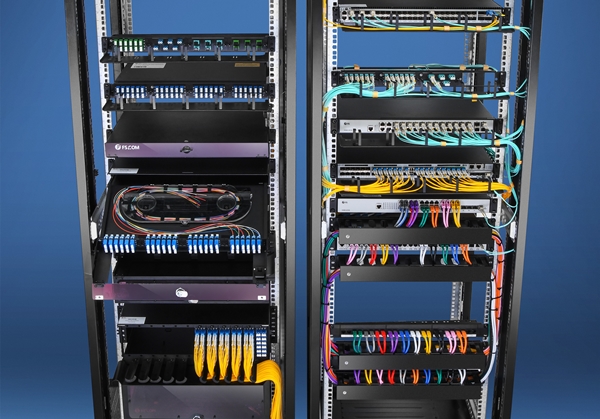

Figure 1: An array of cable management accessories are installed in open server racks to manage cables.

Deploy Proper Server Rack

Above all, estimate your enterprise network scale, cabling numbers and other requirements to choose proper server rack. There are mainly three types of server cabinets in the market, making sure to choose the one for your network environment. All these server racks price are competitive in FS.COM.

- Open Frame Server Rack

The open frame rack has no sides and doors to restrict it from reaching the open air. It provides easy access, sufficient open space and airflow for cable management, ideal for high-density cabling for server room and data center racks. You’d better to use open server rack in applications that don’t require security protection for cables. 2-post and 4-post are two types of open frame racks. The former requires less depth whereas the latter supports more weight.

- Enclosed Server Rack

The enclosed server rack is a sever cabinet with front and back doors and side panels. The doors can be locked to prevent intentional sabotage and dust invasion. Black server rack 42U/45U is available in FS.COM to offer you with abundant rack cabling space. FS elaborately designs efficient brush guards on the roof to facilitate airflow and ensure better cooling.

- Wall Mount Server Rack

Wall mount server rack is used to hold network equipment such as network switch and network accessories such as fiber patch panel. It features functionality to be attached onto the wall to save floor space. FS manufactures 9U/12U 4-post wall mount network cabinets with glass front door. The defect is that wall mount server rack is not as big as other server racks to room large quantity of network devices. In this case bigger network cabinet is the better choice to go. Here is a comprehensive data center cabling solution video guide for your reference.

Deploy Other Cable Management Products in Server Rack

After choosing optimal server racks for your cabling solution, take other cable management accessories into consideration.

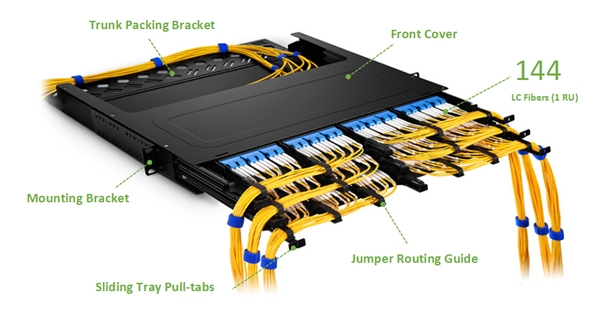

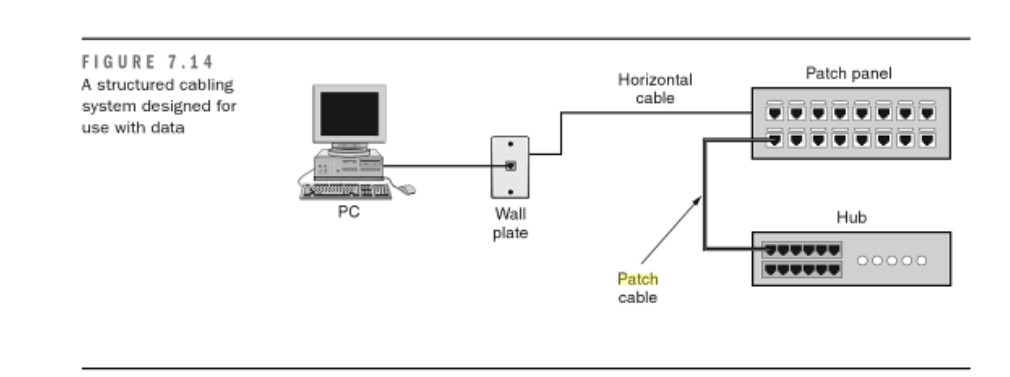

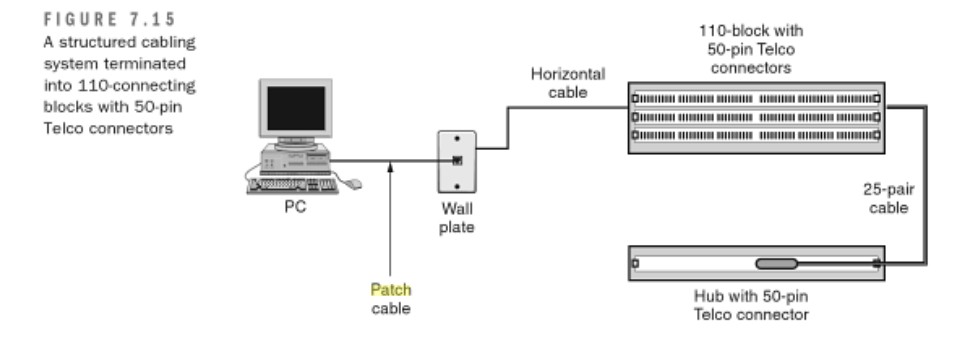

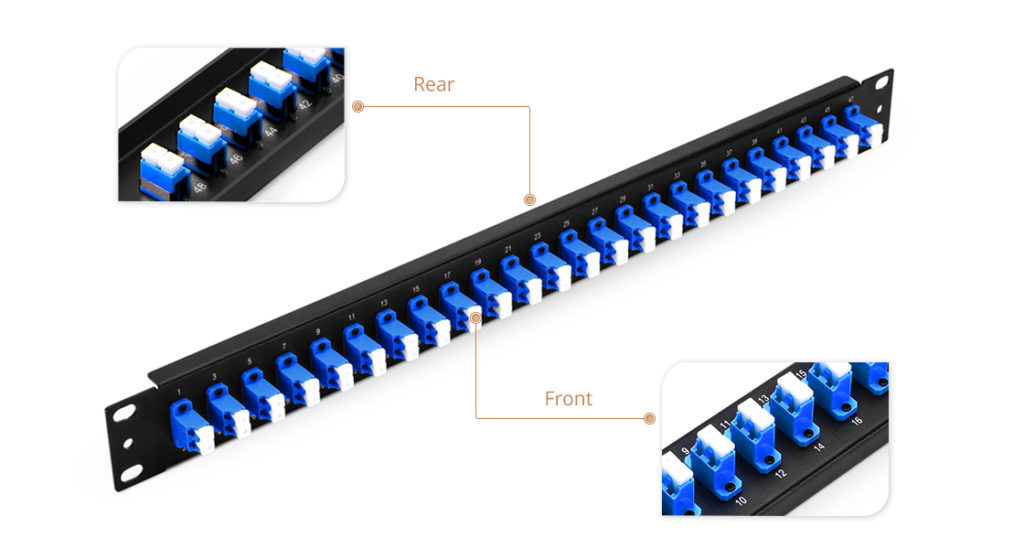

- Deploy right fiber patch panels or cassettes to terminate your fibers, and use matching fiber enclosures to load them and other enclosure accessories such as fiber slack management spool. An intact loaded fiber enclosure ensures safe entry and exist of fiber patch cables and stores an excess of fibers in a compact of 1U/2U/4U.

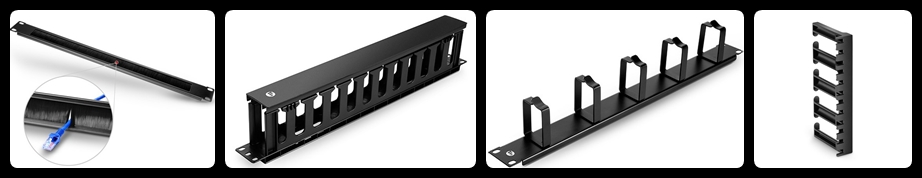

- Use cable organizer – horizontal cable manager and vertical cable manager to keep scattered running cables in right place and ensure a neat rack environment. Besides, employ cable ties/zip ties to fix wire bundles.

- Put emphasis on cable identification tools. Cable ties are available with different colors to help figure different types cables or end devices. Color coded fibers and Ethernet cables are also helpful for recognition. Or you can buy color-coded cable labels with different numbers to mark your wires.

Conclusion

Proper cable management cannot be accomplished in one action. First of all, carefully plan your cabling solution on the basis of your data center scale. Then deploying proper server racks or cabinets and other cable management products – fiber enclosure, fiber patch panel, cable organizer/cable manager, cable ties, cable labels to manage cables shipshape and facilitate cable identification. All these jobs done orderly will make a clean and decent server room, and endow cables and the whole systems with security warranty.

Related Article: