Fiber optic cables are available with a wide variety of constructions to match the unique requirements of virtually any AV installation. These cables may contain just one fiber or hundreds of fibers and may be designed for indoor or outdoor applications. now we mainly examines outlines which cable constructions are appropriate for each topology.

A simplex fiber optic cable, contains a single, tight buffered fiber surrounded by aramid yarn strength members. At the center of the cable, the 125 um glass fiber is surrounded by a 250 um buffer coating. A 900 um secondary buffer is added for additional protection. The aramid yarn is made from Kevlar, the same material used by law enforcement and the military for body armor. It provides additional protection and strength for pulling. A 2mm to 3mm outer jacket surrounds the yarn and buffered fiber for a final layer of protection. As mention simplex fiber optic cable, we have to recommend you 10G OM4 simplex fiber optic cable from FS.COM. As shown in following picture.

Multimode OM4 fiber optic cable is the highest level of multi-mode fiber optic cable that you can use. The om4 multi mode fiber cable has the highest bandwidth possible and therefore can be used in networks where an overwhelming or extreme amount of data transfers will take place. The multimode om4 fiber, or om4 wire, will definitely support all of your businesses data needs.

A duplex zip-cord fiber optic cable, as shown in Figure 12, consists of two simplex fibers that are bound together, and can be easily separated by pulling apart. Each buffered fiber is surrounded by aramid yarn strength members and a jacket. A thin strip of jacket material down the middle holds the two fibers together.

Since most AV signals travel along one or two fibers, simplex and duplex cables are the most common fiber optic cables used in AV systems. They are used as patch cords and are often installed in horizontal spaces between telecom or equipment rooms and work areas. Available in both riser and plenum rated varieties, they can be installed within walls, under raised floors, and in air return spaces. The small size and light weight make these cables easy to pull. The individually jacketed and buffered fibers enable easy field termination, and provide durability for routine handling.

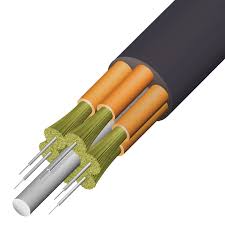

A breakout fiber optic cable contains multiple simplex cables within a common outer jacket as shown in Figure 13. The simplex fibers are bundled around a central dielectric element for additional strength. The outer jacket can be stripped back using an integrated rip cord to expose the simplex fibers for stripping and termination. Once terminated, the individual fibers can be plugged directly into a patch panel or terminal equipment. The jacketing material can be riser or plenum rated for installing in walls or air return spaces.

Breakout cables are used anywhere multiple fibers must be run from one point to another. Since each fiber is protected by strength members and a jacket, breakout cables are often used in horizontal spaces between work areas and a telecom or equipment room. They are also used within the building fiber backbone for connecting the telecom room to the equipment room in a hierarchical topology. Breakout cables can be used between patch panels or plugged directly into equipment.Bulk 9/125 Singlemode Fiber Optic Breakout Cable save up to 30% off in FS.COM now. Our breakout cable is OFNP, plenum rated so it can be placed in ceilings and other plenum air spaces. This series features a single outer jacket which surrounds and protects the individually jacketed fibers within. Our bulk fiber optic cable is compatible to international and industrial standards, we are China manufacturer and China supplier of good price bulk fiber optic cables.

Plastic optical fiber is a type of optical fiber that uses polymethylmethacrylate (PMMA) as the core material that allows the transmission of light. POF is often called consumer optical fiber as it is a low-cost optical fiber alternative that is easier to use than glass optical fiber. It sustains a data transfer speed of 2.5GB/s, which isn’t as fast as glass optical fiber, but is much faster than traditional copper wire.

In comparison to traditional optical fiber, PoF is much larger in diameter which results in lower data rates making it most suitable for high bandwidth signal transmission over short distances. Unlike glass, plastic fiber can easily be cut and bent to fit in hard-to-reach places and the larger core also allows for slightly damaged fiber to work. POF products are most commonly used in medical, automotive, home networks, as well as digital audio and video interfaces. Our Plastic Fiber Optic Cable is constructed of a single acrylic monofilament and are most efficient when used with visible red status indicator light sources.A wide range of fiber optic tips are available.

Fiber optic cables provide unique advantages in an AV system, particularly in secure and long distance applications. Choosing the proper cable depends upon the number of fibers required, installation location, topology, and the overall design of the system. Cable constructions are available for both indoor and outdoor applications to provide a solution for virtually any AV system. Color coding provides an easy identification method for multi-fiber cables.