Recognizing the need for enterprises to have a dedicated area within a building for connecting servers to internal and external networks, otherwise known as data centers, the Telecommunications Industry Association (TIA) developed and ratified the TIA-942 standard. Data centers operate at very high levels of reliability and demand design flexibility to easily accommodate frequent adds and changes to equipment. Managing the thousands of cables that typically comprise a data center should always be a high priority for the data center or network manager particularly for maximizing system performance and uptime.

Fiber plug-and-play solutions for data center applications are designed to address the reliability, scalability,and thermal needs of today’s mission-critical data centers. The product suite includes plug-and-play MPO Cabling solutions for TrueNet Fiber products for placement in the main distribution area (MDA), backbone, and horizontal and equipment distribution areas (HDA and EDA). These solutions are included in the TrueNet Zero Bit-Error Warranty, and promote increased reliability of the data center through properly managed and scalable cable density, which encourages proper airflow and reduces overall installation and maintenance costs.

Polarity Made Simple

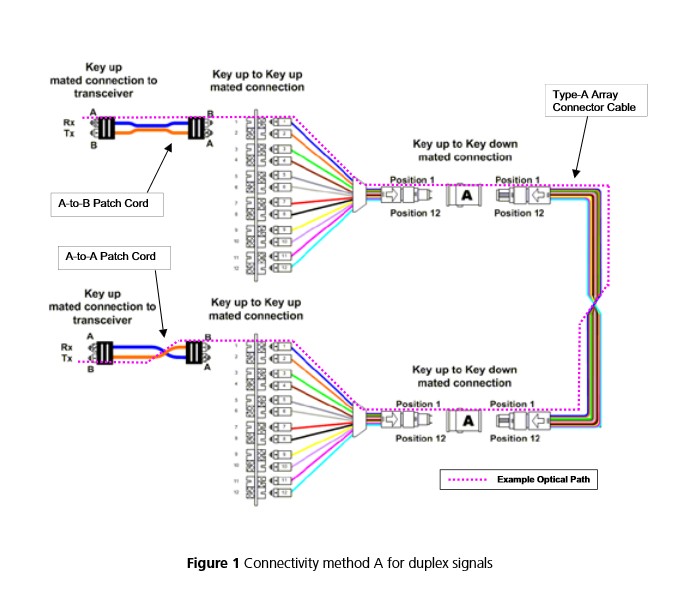

One of the most common questions regarding MPO deployments is how the system design addresses the polarity issue of the fiber. Fiber system employs the recommendations made in TIA standard TIA-568.b.1-7.Fiber plug-and-play trunks use a key up/key down fiber array as noted in TIA-568.b.1-7. The Fiber plug-and-play cassettes are wired straight through. In addition, Fiber duplex jumpers have a duplex clip that is easily removed for polarity changes in the field.

Of main concern in the horizontal and equipment distribution areas is the consolidation and management of optical jumpers from Storage Area Networks (SANs), servers, switches and routers. Fiber optic panels at these consolidation points should employ four fundamentals of fiber management: bend radius protection, cable and connector access, intuitive cable routing paths, and physical protection.

Horizontal and Equipment Distribution Areas

Data Center Optical Distribution Frame (ODF) is the highest density fiber distribution frame solution available on the market. It efficiently manages up to 1,728 fiber terminations using the 144-position block (or 2,304 using the 192-position block) in a single frame in either a cross-connect or interconnect design. The data center frame’s patented design incorporates the fundamentals of cable management while using the industry’s highest fiber count MPO Cassette. This powerful combination provides the following benefits:

- Rapid installation of new deployments

- MPO trunks can enter the rack from under-the-floor or overhead

- Slack storage included in each rack allows for the use of a single jumper length

- On-frame jumper routing provides bend radius and physical protection for easily managing slack

Backbone Cabling

In order to maintain the optimum performance of servers and switches, the TIA standard recommends incorporating hot aisle/cool aisle into the data center architecture.In a raised floor environment it is important to maintain proper airflow to promote the optimal cooling of active electronics. Ideal airflow requires proper design to prevent unintended air dams that will reduce data center reliability and efficiency. Moving the fiber optic cabling overhead frees up space in the raised floor to promote proper airflow.

FS.COM Plug-and-Play MPO trunk assemblies are round 12 fiber trunk cable pre-terminated with a high-density MPO connector on both ends. They can be used in conjunction with any of the other plug-and-play connectivity products to rapidly deploy fiber into a data center. The MPO assemblies can simply be connected to any plug-and-play cassette in the optical distribution frame or fiber enclosure which eliminates the need for on-site fiber termination and preparation. The Plug-and-Play trunk consists of a round Kevlar reinforced cable with integrated MPO strain relief and optional pulling eye. Its total outer diameter is 5.5mm.