In network setups we see everything is plugged into a switch, but before that fiber cables are also connected to another supply – patch panel. Thus one question is often confusing: patch panel vs switch: What’s the difference and what’s the significant function of them respectively?

What Is Patch Panel?

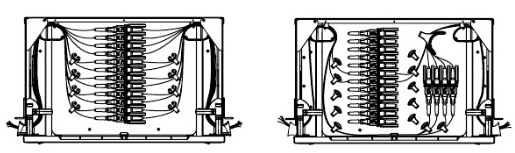

Patch panel (fiber optic patch panel, fiber optic enclosure) is a terminate unit of network ports centralized together. It is a cable management solution component used to organize fiber cables and keep everything neat for a clean wiring closet. In data centers, a mass of cable wires scattering all over and mixed together can be bothersome, in this case a patch panel is indispensable and rather helpful. It not only offers ease of management, but also protect the terminations from being knocked. Besides the fiber optic patch panel, other cable management accessories including cable ties and cable labels are also used to keep cables tidy and easy for identification.

Figure 1: This photo shows the application of patch panel by FS.COM for cable management in a data center.

What Is Switch?

Switch, commonly known as network switch, is an appliance in a data center that connects all devices (such as PCs and servers) as a whole to achieve intercommunication and data sharing between different network devices. It channels the incoming data from multiple input ports to the specific output port so as to deliver the data toward its destination. In Ethernet LAN or WAN, modern network switch usually determines which output port to use by network address.

Figure 2: This photo shows the application of network switch by FS.COM in a data center.

Patch Panel vs Switch: What’s the Difference?

Table below shows the main difference of patch panel vs switch.

Comparing patch panel vs switch, we can make the following conclusion. Patch panel is nothing but an essential cable management tool, which exerts no functional influence to the performance of data transmission. However, a switch is an irreplaceable functional supply in network setups.

Why Patch Panel Is Commonly Set Up in Network Installation?

As mentioned above, patch panel has no effect on the data transmission process. Can it be omitted in fiber optic cabling? Or can wires just directly plugged to a switch? The answer is yes when you just deal with several fiber cables. However, Ethernet patch panel is a must in data centers where there are a large number of Ethernet drops. No doubt you don’t want to see all the things tangled together. A patch panel in place provide ease management of classification, maintenance, repair, installation and upgrades.

Conclusion

This article gave an brief introduction to patch panel and switch respectively and then discussed the differences between them. Patch panel vs switch : what’s the difference, and why is a patch panel commonly set up in network installation whereas a switch is already used? Can you answer these questions now? Simply put, patch panel is an essential cable management tool whereas network switch is a significant functional supply in data center. Both of them play important role in their respective positions.