Bend insensitive multimode fiber (BIMMF) has become a very active area within the telecommunication industry once it was introduced and popularized. It typically signifies technical advancements in the production of multimode optical fiber for easier installation, and cable management for multimode fiber cables through improvements in bend insensitivity. This article will focus on some useful information about BIMMF from the perspective of its working principle, performance in networking and unique advantages as well.

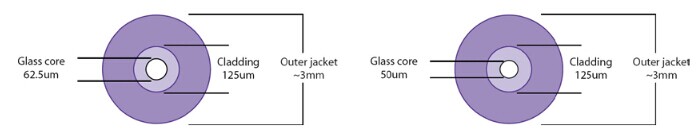

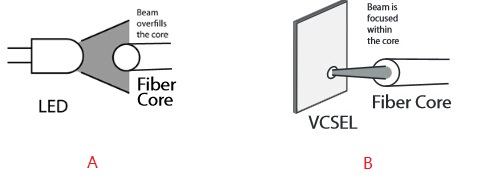

An optical fiber consists of a core and a cladding. Although both of these regions are made from glass in telecommunications grade fibers, they are significantly different from each other. Each region is designed to capture light within the core and transmit it to the opposite end of the fiber. During this process, the light may follow many paths, depending on the angle at which the light hits the boundary, it is either reflected back into the core, or it gets lost into the cladding. Therefore, the light losses during transmission cause a weaker optical signal at the other end.

Optical fiber is sensitive to stress, particularly bending. When conventional fibers are bent tightly, some of the signal will leak out of the fiber at the site of the bend due to macrobend loss, which will results in system failure and unplanned downtime. Various attributes in the fiber determine when this occurs. The relative ease with which this happens is known as bend sensitivity. On the contrary, bend insensitivity is a positive feature that can provide for additional robustness and simplify installation of multimode fiber.

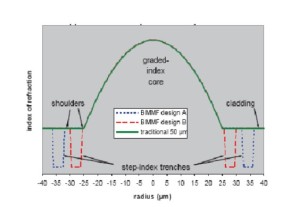

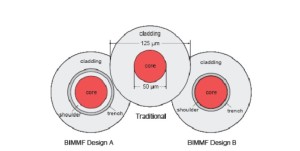

Bend-insensitive multimode fiber (BIMMF) has an innovative core design that enables it to significantly reduce macrobend loss even in the most challenging bend scenarios. It is hence natural that bend insensitive multimode fiber can withstand tough treatment. The difference between traditional multimode fiber and BIMMF mainly lies in the fact that the BIMMF design can include an optical trench. This trench effectively improves the fiber’s macrobend performance by retaining more of the light that would have escaped the core of a traditional multimode fiber. So when compared with standard multimode fibers, BIMMF is proved to be a good candidate for loss and bend critical applications because of their higher immunity to bending losses, without loosing performances or compatibility to other standard high bandwidth multimode fibers.

There is a lot of buzz around the issue of bend insensitive fiber— is it compatible with regular fibers? Can they be spliced or connected to other conventional fibers without problems? Modeling and testing on BIMMF has shown that an optimized BIMMF is backward compatible and can be mixed with non-BIMMF without inducing excess loss. Hence, BIMMF and MMF could easily be mixed in an optical channel without complicating the estimation of losses. Moreover, BIMMF may lead to higher tolerance to possible misalignments when two connectors are mated. This is an additional positive feature for 40 and 100 Gigabit applications.

In summary, a well-designed BIMMF complies with all relevant industry standards and adheres to the following:

- BIMMF OM2, OM3 and OM4 multimode fibers are fully compliant and fully backward-compatible with all relevant industry standards.

- BIMMF is fully backward-compatible and may be used with the existing installed base of 50/125um multimode grades including OM2, OM3 and OM4.

- BIMMF may be spliced or connectorized to conventional 50/125um fiber types with commercially available equipment and established practices and methods, no special tools or procedures are required.

- BIMMF not only meets all relevant macrobend standards, but sets a new level of bend performance.

Bend insensitive multimode fiber is available in all laser optimized grades, OM2, OM3 and OM4, and exhibits 10 times less signal loss in tight bend scenarios and therefore protects enterprise and data center systems from unplanned downtime due to signal loss and associated significant revenue loss.

This fiber type offers extremely low bending loss at both the 850 and 1300 nm operating windows, while maintaining excellent long term fiber strength and reliability. The fiber can be installed in loops as small as 7.5 mm radius with less than 0.2 dB bending loss at 850 nm and 0.5 dB at 1300 nm.

| Maximum induced bend loss performance at 850 nm | Standard for multimode fibers IEC 60793-2-10 | Bend Insensitive MMF (no standard currently) |

| Bend radius | 37.5 mm | 7.5 mm |

| Number of turns | 100 | 2 |

| Conventional MMF | 0.5 dB | – |

| Bend Insensitive MMF | 0.05 dB | 0.2 dB |

In addition, bend insensitive multimode fibers enable new possibilities for cable and patch panel design to further improve the benefits of using fiber. Optical cable manufacturers can now design thinner, more flexible trunk cables, making for easier cable installation and further improving airflow in conduits, patch panels and racks. Due to the ability of the fib cable to be bent tightly with significantly less signal loss, connector modules can be made smaller which in turn leads to an increased density within racks and smaller racks.

Bend insensitive multimode fiber has been widely employed to enhance fiber management in data centers, high performance computing and enterprise LANs. Since it is a real advance to current standard multimode fibers, BIMMF is recommended for bend and loss critical applications. What should be noticed is that BIMMF also should be handled with appropriate care as all optical glass fibers.