Fiber optic connectors, as one of important linking components, can be found everywhere in fiber optic networks. With fiber optic connectors, you can easily add, drop, move and change the networks. And it’s also well known that a clean and reliable optical connector can provide high performance fiber infrastructure and extend the life of network. Then how much do you know about fiber optic connectors cleaning? Today, these questions may help you know more about it.

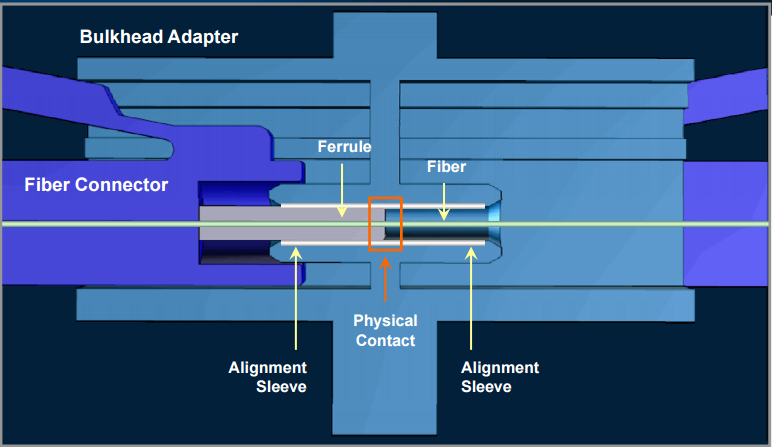

Cleaning consideration is a crucial issue in fiber optic cable technology today. If not cleaned properly, the ferrule in connectors is easy to be damaged when connecting, which can result in high costs. What’s more, it’s known to us that the fiber ferrules in the connectors make physical contact with another within the connectors alignment sleeve. Any contamination or dirt on one of the ferrules can easily be transferred to the mating ferrule, which can cause physical damage to the fiber’s end-face and further lead to information transmission failures. Hence, fiber optic connectors should be cleaned carefully.

Generally, there are two ways to clean fiber optic connectors. One is dry cleaning, and another is wet cleaning. Following is a brief introduction.

Usually, dry cleaning is to use a reel-based cassette cleaner to wipe the connector end-face against a dry cleaning cloth in one direction. For APC (angled physical contact) polished connectors, it’s essential to ensure the end-face surface mates with the cleaning cloth. Generally, dry cleaning can remove airborne contamination.

As for wet cleaning, first wipe the end-face against the wet area and then onto a dry area to clean potential residue from the end-face. Wet cleaning is more aggressive than dry cleaning, and can remove both airborne contamination and light oil residue.

With more and more fiber optic components widely used, fiber optic cleaning is required for an optimum connection between both active fiber equipment and passive fiber equipment. Without cleaning, your network performance and reliability can be influenced. Here recommends two common types of fiber optic cleaners.

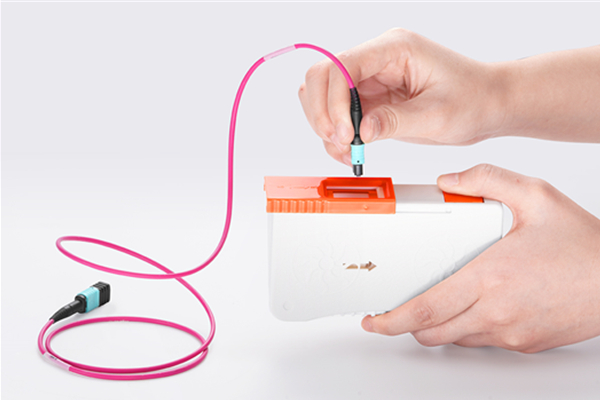

One-push cleaner is designed to clean male connectors, female bulkhead adapters, fiber patch cables and test equipment. It cleans the ferrule end-face by removing dust, oil and other contamination without scratching the end-face. FS provides several kinds of this cleaners such as one-push cleaner for LC/MU 1.25mm ferrules, one-push cleaner for SC/ST/FC/LSH 2.5mm ferrules, one-push cleaner for MTP/MPO connector and so on.

The cassette cleaner can wipe away contamination from optical connector end-face with ease. It’s very easy to use and suitable for LC/SC/FC/ST/MU/D4/DIN connectors. Usually, the body of this cleaner is made from antistatic materials which will not produce dust. And the common type of cassette cleaner is CLE-BOX fiber optic cassette cleaner.

There are various ways to clean fiber optic connectors. But we still should be careful when cleaning fiber optic connectors because they are easily damaged. Following are some helpful notes that should be given attention to when cleaning connectors.

- Do not forget to inspect the fiber optic connector, component, or bulkhead before starting cleaning.

- Do not allow the end of the fiber optic connectors to contact with any surface including fingers.

- Do not use alcohol or wet cleaning if no residue left on the end-face. It can do harm to the equipment.

- Do not push it with heavy pressure. Use the fiber optic cleaner correctly by inserting it at the correct angle and clean connectors carefully.

- Do not forget to reinspect the connectors when cleaning has been finished.

Keeping fiber optic end-face clean is extremely important and one of the most critical requirements for ensuring accurate measurements and operation. Hence, choosing suitable cleaning tools for fiber optic connectors is significant. FS provides a number of fiber optic cleaning tools such as pen cleaner, cassette cleaner and so on. All this cleaning tools have good quality and high performance, which can make your fiber optic cleaning works easier and more convenient. Welcome to contact sales@fs.com.