Optical fiber is utilized for high-speed and error-free data transmission across connector assemblies. So the connector end faces need to be polished to optimize performance. And also the connectors must follow acceptance criteria related to insertion and back reflection loss as well as end-face geometry specifications. This article will talk about the fiber optic connectors polishing.

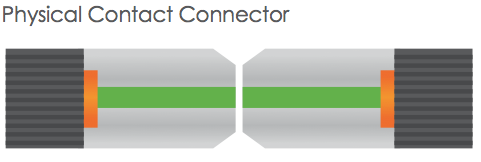

Early physical contact connectors required spherical forming of their flat end faces as part of the polishing procedure. It involved a four-step process: epoxy removal, ferrule forming, and preliminary and final polishing. These steps utilized aggressive materials for epoxy removal and ferrule forming, generally accomplished with diamond polishing films. Now the polishing process has developed into a sequence of epoxy removal, followed by rough, intermediate and final polishing cycles because almost all connectors are manufactured with a pre-radiused end face. One goal is to avoid excessive disruption of the spherical surface, while still producing a good mating surface.

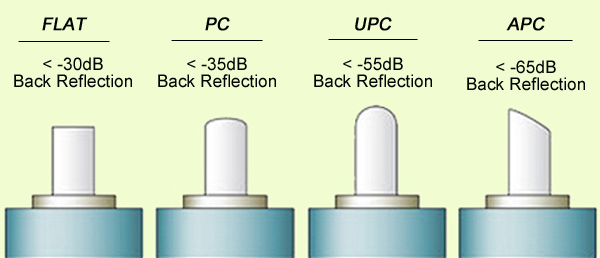

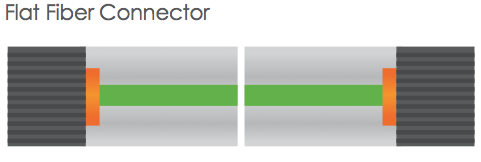

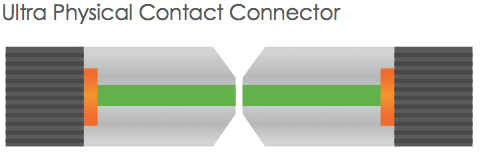

Polishing specifications for fiber connectors fall into two categories related to performance and end-face geometry. Back reflection and insertion loss specifications are the most critical measures of polished end functionality. The insertion loss is the amount of optical power lost at the interface between the connectors caused by fiber misalignment, separation between connections (the air gap) and the finish quality of each connector end. The current standard loss specification is less than 0.5 dB, but less than 0.3 dB is increasingly specified. Back reflection is the light reflected back through the fiber toward the source. High back reflection can translate to signal distortion and, therefore, bit errors in systems with high data transfer rates.

Today several types of connectorized fibers are available, the most common of which are 2.5 mm, 1.25 mm and multifiber. Connector end faces must first be air-polished to ensure a proper mating surface. This will be followed by a sequence of polishing steps depending on the type of connector, the back reflection and the insertion loss specifications. Regardless of the connector type, most polishing sequences begin with aggressive materials, including silicon carbide to remove epoxy and diamond lapping films for beginning and intermediate polishing. These remove both surrounding material and fiber at the same rate. But the last polishing step needs a less aggressive material to attack only the fiber, such as silicon dioxide. Using a material for final polishing that is too aggressive could result in excessive undercut. The wrong final-polish material can cause excessive protrusion, leading to fiber chipping and cracking during the connector mating process.

Issues to be examined include the polishing films used, the type of epoxy and lubrication. Films are the most significant impact because the gradations and quality vary from supplier to supplier. End users should pay attention on selecting film type. Excessively aggressive films can destroy a 125-μm fiber and the end-face radius. Epoxy removal is also essential to contamination-free polishing. Some types of epoxies can be removed more easily with specific grades of silicon-carbide polishing films. The films to use in this step depend on the size of the epoxy bead mounted on the connector end face and the epoxy type. Epoxies have different varieties. Some will be tacky, some firm. In all, a contamination-free environment is essential to optimizing connector polishing.

Polishing may be an old art form, but for the immediate future, it’s here to stay. Undoubtedly inspection criteria will increase. Polishing procedures will be driven to change, and new connector style will also make us continuously strive to reinvent our approach to polishing. Fiberstore has various products about fiber optic polishing. For more details, please visit FS.COM.