How long have you ever spent on cable installation? As we all know, cable deployment in the network is a time-consuming work. However, with the help of pre-terminated systems and components, you can cut installation time effectively, for there is no need to do field terminations or splicing during installation. Now, this article focus on one of the pre-terminated cables—pre-terminared copper trunk cable.

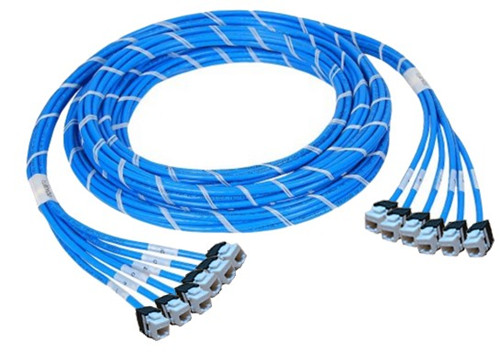

In simple terms, pre-terminated copper trunk cable is a kind of cable which has gone through the same procedures with other cables, but their connectors have already been terminated, properly polished, and the entire cable assembly tested on either both or one end in factory. Copper trunk cables are typically comprised of bundles of 6, 8, or 12. Since they are bundled together, there is no need to worry about cable mess. Pre-terminated copper trunk cables provide a quick “plug-and-play” solution for links between switches, servers, patch panels, and zone distribution areas in the data center, and they are preferred when the cable distances are less than 100 meters and cable lengths are pre-determined. Here is a picture of pre-terminated copper trunk cable.

Besides, the common types of pre-terminated copper trunk cables are Cat5e, Cat6, Cat6a, Cat7, etc. And different types have different advantages and specifications. All of them are necessary elements for data transmission in the enterprise and data center networks.

In today’s workplace, quick and easy cable installations that guarantee reliable performance are more critical than ever. When compared to field-terminated cabling, there are many reasons to consider pre-terminated category-rated cables in copper network.

It’s know to us that field termination is time-consuming in cable installation. If not use pre-terminated cables, much time would be spent on cable packages and connections. According to some figures, deploying pre-terminated cabling can reduce installation time by up to 75 percent over field terminations.

During a cabling installation, installation and transmission performance testing cost too much time. However, pre-terminated copper trunk cables are terminated in factory, and many of them are provided in a cassette format. This format allows installers to “plug and play” multiple connections with one cassette, which reduce installation time obviously. Besides, transmission testing has been performed by manufacturers before shipment, which also reduces time when installation.

Pre-terminated trunk cables contribute to data center modularity and consistency, making cabling more accessible and organized. And they also remove excess loops, thus storing excessive slack is not a concern.

Of course, apart from what have been mentioned above, there are also other benefits for applying pre-terminated copper cables such as space saving, cost saving and labor saving. In a word, pre-terminated copper trunk cable deployment benefits cable installation a lot.

We have known the benefits of using pre-terminated copper trunk cable. But do you know how to choose a suitable one? Here are several factors you should consider when choosing a right copper trunk.

There are different problems may arise in data center and fire is one of them. So there is a need to consider the fire ratings of material. Generally, a riser environment is very common in data center, for in there airflow is not a consideration. But some areas such as drop ceilings and raised floors often require plenum-rated cable which can facilitate air circulation for heating and air conditioning systems.

The termination type of the cable assembly depends on the layout of the data center or telecommunications room, and the design philosophy employed. Different types have different requirements for installation. Common termination types are jack-to-jack, plug-to-open-end, jack-to-plug and plug -to-plug.

A proper breakout length, referring to the length from the end of the braided sleeve to connectors at the end of the cables, offers the flexibility to route the cables as needed. So it’s important to have a right breakout length.

In addition, cable length and the alignment also should be taken into consideration. Of course, how to choose a suitable pre-terminated copper trunk cable also should depend on your real applications.

Pre-terminated copper trunk cable provides a perfect cost-effective solution for enterprise and data center applications. Choosing a right one will help you resolve many unnecessary problems during installation process.