Fiber optic cables come in many configurations. The fiber strands can be either single mode or multimode, step index or graded index, and the cable jacketing can be either tight buffered or loose-tube buffered. The fiber strands have a variety of core diameters. Most often, the fiber strands are glass, but plastic fiber optic cable exists as well. Finally, the cables can be strictly for outdoor use, strictly for indoor use,or a “universal” type that works both inddors and out. These cables also have various fiber ratings. This article mainly introduce the number of optical fibers.

The difference between fiber optic cables is the number of individual optical fibers with them. The number depends on the intende use of the cable and can increase the cables’s size, cost, and capacity.

Because the focus of this book is network cabling and the majority of fiber optic cables you will encounter for networking are tight buffered, we will limit our discussions here to tight-buffered cables. Thes cables can be divided into three categories based on the number of optical fibers:

- Simplex cables

- Duplex cables

- Multifiber cables

A simplex fiber optic cable has only one tight-buffered optical fiber inside the cable jacket. Because simplex cables have only one fiber inside them, only aramid yarn is used for strength and flexibility; the crimped directly to a mechanical connector. Simplex fiber optic cables are typically categorized as interconnect cables and are used to make interconnections in front of the patch panel.

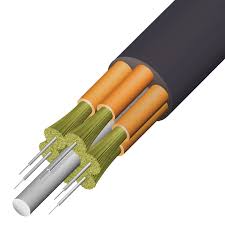

Duplex cables, in contrast, have two tight-buffered optical fibers inside a single jacket (as shown in Figure 8.12). The most popular use for duplex fiber optic cables is as a fiber optic LAN backbone cable, because all LAN connections need a transmission fiber and a reception fiber. Duplex cables have both inside a single cable, and running a single cable is of course easier than running two.

One type of fiber optic cable is called a duplex cable but technically is not one. This cable is known as zip cord. Zip cord is really two simplex cables bonded together into a single flat optical fiber cable. It’s called a duplex because there are two optical fibers, but it’s not really duplex because the fibers aren’t covered by a common jacket. Zip cord is used primarily as a duplex patch cable. It is used instead of true duplex cable because it is cheaper to make and to use. Most importanly, however, it allows each simplex cable to be connectorized and crimped directly to a mechanical connector for both strength and durability. Figure 8.13 shows a zip cord OM4 fiber optic cable.

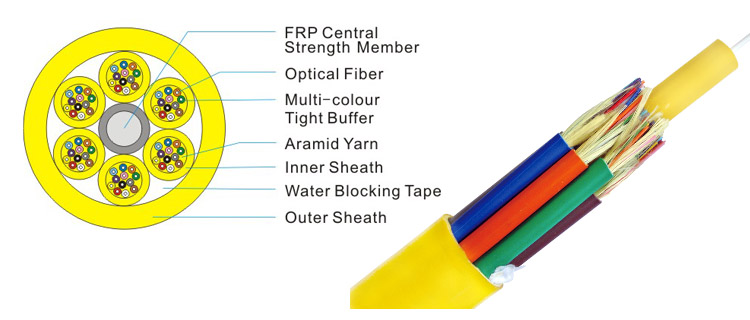

Finally, multifiber cables contain more than two optical fibers in one jacket. Multifer cables have anywhere from three to several hundred optical fibes in them. More often than not, however, the number of fibers in a multifiber cable will be a multiple of two, as discussed earlier, LAN applications need a send and a receive optical fiber for each connection. Six, twelve, and twenty-four fiber cables are the most commonly used for backbone applications. These cables are typically used for making connections behind the patch-panel (aslo known as “behind the shelf” connections).

FS.COM specialize in fiber optic cables with expert advice, large in-stock inventory of bulk fiber optic cable and a high level of customer service. Bulk fiber optic cable are available in simplex, duplex, breakout, distribution and indoor, outdoor types. Other types also available for custom design. Excellent quality and fast delivery.