Sensing fiber optic cable is a type of optical cable that can monitor temperature, strain, acoustics and pressure. They are suitable for a wide range of applications like fire detection, vibration monitoring, industrial plant temperature sensing, temperature gradients in soil, pipeline leak and intrusion detection. Although these cables are built based on standard fiber optic cable which only operates to 85℃, the highest working temperature of them is up to 700℃. Before knowing what benefits that sensing fiber optic cable could bring to our life, let’s figure out the common types of sensing optical cable at first.

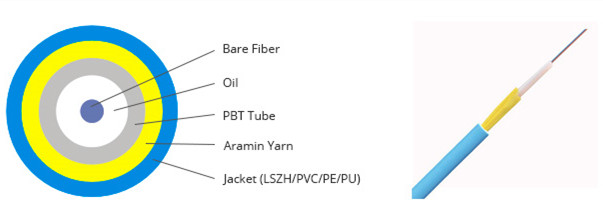

The major difference of this optical cable is that the bare fiber inside is protected by a PBT tube. Except that, it is comprised of fiber, oil, aramid yarn and a sheath which can be made of different materials such as PVC, LSZH, PU and PE. With the unique structure, this sensing fiber optic cable is suitable for applications in subway systems, tunnels and fire protection industries to sense temperature and pressure, helping to prevent disasters and accidents.

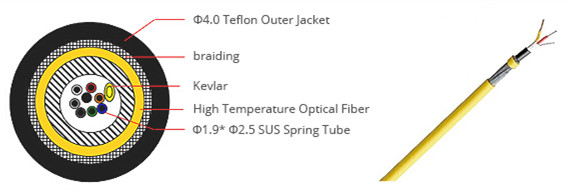

Armored fiber optic cable is very common in optical communication. However, this kind of armored sensing cable is a little different. They are strengthened by both SUS spring tube and SUS braiding, which bring them very good mechanical performance of tensile resistance and pressure resistance. Therefore, these cables are widely applied to fire detecting, building health detecting and temperature detecting.

Teflon, or PTFE (Poly tetra fluoroethylene) is used in a wide variety of high temperature applications like gas turbine and high voltage gas ignition wires due to its higher melting point. Besides, the aramid yarn and stainless steel braiding ensure good crush-resistant performance and the tensile strength of the cable. With all these characteristics, Teflon sheathed sensor cable is a good choice for high temperature resistant environment and fiber temperature sensing systems.

This armored fiber optic cable consists of bare fiber, oil, seamless stainless steel tube and an outer jacket. This structure brings a high tensile strength, crush resistance, a compact size and an unmatched steel performance to this fiber cable. And it features a simple structure and small size, but providing prominent transmission performance. With this sensor cable, some accidents that frequently occur in places such as tanks and mines can be avoided.

As its name shows, there is a copper braiding around the outer jacket of this sensing cable. Copper braid is made from weaving together strands of copper wire. The flexibility of the braid is determined by the diameter of the copper wire. The smaller the wire, the greater the flexibility. And the larger the volume occupied by the braid, the more expensive the braid becomes. Apart from the copper braiding, there are stainless steel flexible tube and stainless steel braiding outside the bare fiber, which make the cable more suitable for outdoor optical fiber communication and optical fiber sensor. With the copper braiding structure, the special cable can prevent the external electromagnetic field on internal invasion, reducing its optical transmission loss.

Unlike copper braid armored sensor cable, the silica gel sensing optical cable has a very simple structure, including bare fiber, Teflon tube, armored yarn and silicone jacket. As have mentioned above, Teflon is a high performance alternative insulation. With the silica gel that is another kind of good insulation material, both of them make this sensing fiber optic cable an ideal solution for high temperature resistant and high voltage environment. It can work normally even in the 250℃ high temperature environment or 6kv high voltage environment without affecting optical signals’ transmission.

The deployment of sensing fiber optic cables brings us lots of benefits in various applications. They can be applied in downhole to monitor temperatures either as DTS or datacom links to sensors; they can be deployed in power distribution networks to monitor performance of power cable systems; they can be attached to pipelines for temperature data that’s available on demand. This post introduces six kinds of sensing fiber optic cable. All of them are available on FS.COM. Welcome to contact us via sales@fs.com.