In a power-splitting PON, an optical power splitter is the passive device in the outside plant that physically connects to the CO with a feeder fiber. It also connects to a number of ONUs via a series of distribution fibers. In the past few years, significant improvements in reliability, cost per port, insertion loss, and splitting-ratio nonuniformity, have been demonstrated with planar lightwave circuit (PLC)-based splitters. Central to the splitter is a PLC chip comprising of optical waveguides fabricated on a planar substrate, typically made of silicon or quartz, to form a cascade of Y-branches. For a 1 × splitter, one side of the PLC chip is aligned to a fiber whereas the opposite side is aligned to an array of PON is typically N = 16 and N = 325, but with an increasing demand of up to N = 64, thereby making the alignment of the fiber array to the PLC chip more challenging. Compared to fused biconical-taper-based splitters, PLC technology allows for chip-size devices with the potential of integrating multiple functions, e.g. WDM coupler, onto a single clip. It also enables a more uniform loss over a wide operating range of wavelengths from 1250 nm to 1625 nm, and operaton of a wide range of temeratures from -40℃ to + 80℃. Figure 3.2 illustrates the measured insertion losses from samples of 1×32 optical splitter approved by AT&T Labs for use in the Project Lightspeed FTTH trial, showing uniform loss over a wide wavelength range.

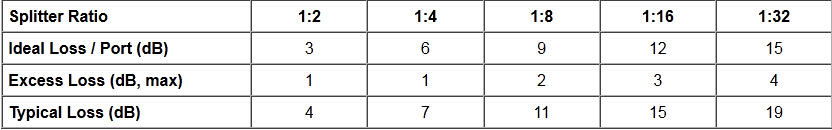

Aside from uniform loss, the insertion loss of PLC splitters is another important parameter in network implementations that will influence system performance and the overall coast per drop. Lower insertion loss PLC slitters will extend the reach and number of customers that can be accommodated within the same PON, yielding higher revenue per PON for service providers. Aside of the theoretical splitting loss attributed to the division of optical power at the input port equally into N output ports, and given by the fromula:

Theoretical splitting loss (dB) = 10 × log10(1/N)

A PLC splitter suffers from excess insertion loss from fiber array alignment to the PLC chip, fiber array uniformity caused by pitch and depth inaccuracies in the v-grooves of fiber array block that holds the fiber array, splitting ratio uniformity caused by imperfections in the PLC chip due to manufacturing, inherent chip material loss, and inherent chip material loss, and connector loss. The targeted areas for improvement of insertion loss in PLC splitters have been in reducing connector losses, and improving fiber array and splitting ration-nonuniformity. The connector loss can be improved from 0.5 dB trough using high quality ferrules and an excellent polishing method. With advances in manufacturing process of the fiber array block and PLC chip, insertion losses from fiber array nonuniformity and splitting-ratio nouniformity can be reduced from 0.7 dB to 0.4 dB and 1.8 dB to 1.0 dB, respectively. Collectively, the excess insertion losses of PLC splitters are currently 1 – 1.5 dB above the ideal theoretical splitting loss with a nonuniformity within 2 dB over the specified range of operating wavelengths from 1250 nm to 1625 nm.

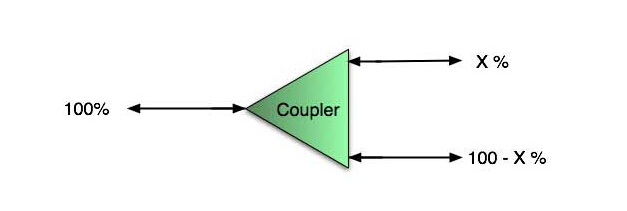

Fiber optical splitter is used to split the fiber optic light into several parts at a certain ratio . The fiber optic splitter is an important passive component used in PON FTTX networks. There are mainly two kinds of passive FTTH optical splitters: one is the traditional fused type splitter as known as FBT coupler or FBT WDM optical splitter, which features competitive price; the other is the PLC splitter based on the PLC (Planar Lightwave Circuit) technology, which has a compact size and suits for density applications. The common PLC Splitters configurations are 1×4, 1×8, 1×16, 1×32, 1×64 and 1×128, but 2×4, 2×8, 2×16, 2×32 configurations are also available. Fiberstore singlemode& multimode FBT optical splitter comes in a wide range of split ratios with single/double/three windows. The main packages include box type and stainless tube type. The former is usually used with 2mm or 3mm outer diameter cable, while the latter is usually used with 0.9mm outer diameter cable. Our optical splitter can be terminated with your choice of connectors or installed in rack mount modules. Please contact us for the special customized needs.

.jpg)