Thanks to the advances made in fiber optical technologies, fiber solutions have been deployed in ever-increasing applications where high-speed and high-performance data transmission is needed. They outweigh the copper solutions in such aspects as higher bandwidth, longer distances and Electromagnetic interference (EMI) immunity. Transceiver module, one of the key components required in such fiber connections for high networking performance, have experienced the never-ceasing industrial designs, from lower port density to higher, from the standard modules to the final hot-pluggable ones, to meet the ever more flexible networking infrastructure.

There is a broad selection of hot-pluggable transceiver modules available for fiber networking use, and you may feel a little confused about how to select the correct transceiver module for your networking transmission. In this article, I will illustrate different aspects of transceivers that need to be known before choosing a transceiver.

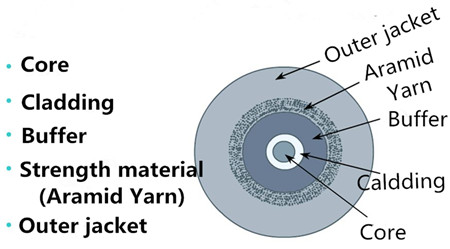

Before giving guidance to transceiver selection, it’s necessary to know the basics of transceiver. Transceiver is a combination of a transmitter and a receiver in a single package, while they function independently for bidirectional communication. Typically, a fiber optic transceiver converts the incoming optical signal to electrical and the outgoing electrical signal to optical. More specifically, the transmitter takes an electrical input and converts it to an optical output from a laser diode or LED. The light from the transmitter is coupled into the fiber with a connector and is transmitted through the fiber optic cable plant. The light from the end of the fiber is coupled to a receiver where a detector converts the light into an electrical signal which is then conditioned properly for use by the receiving equipment.

Here go the several aspects of transceiver modules that are helpful in your purchasing.

Multi-source agreements (MSAs) between different equipment vendors specify guidelines for electrical and optical interfaces, mechanical dimensions and electro-magnetic specification of a transceiver module. The equipment vendors follow these MSA defined values for designing their systems to ensure interoperability between interface modules. The form-factor or the MSA-type is needed so that the transceiver can mechanically and electrically fit into a given switch, router, etc. Transceiver MSAs define mechanical form factors including electric interface as well as power consumption and cable connector types. There are various MSA types: SFP (eg. MGBSX1), SFP+, XFP, CFP, CFP2, CFP4, QSFP and so on.

Transceivers can work over single-mode fiber (SMF), multi-mode fiber (MMF), and copper. In different Ethernet applications, media can achieve different link lengths when combined with transceivers. Take Gigabit Ethernet (GbE) applications for example, single mode SFP transceivers can have a transmission distance of 5km to 120km, while multimode SFP transceivers are defined to have the maximum reach of 55om, with copper solution establishing even fewer link length at 25m. Take MGBLX1 for example, this Cisco compatible 1000BASE-LX SFP works through SMF for 10km reach.

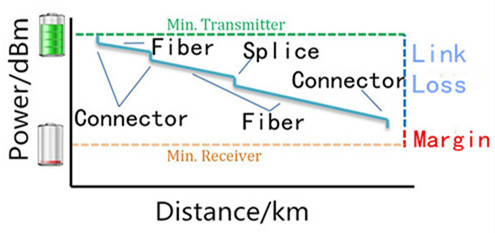

The transceiver power budget is the difference between transmitter launch power and receiver sensitivity and has to be 2-3dB larger (Margin) than the measured link loss. If the link loss cannot be measured, it has to be calculated. Therefore transmission distance [km], the number of ODFs, patches and passive optical components (Muxes) have to be known. Common values for power budget are <10, 14, 20, 24, 28, >30dB.

If you’re seeking high-speed data carrier, transceivers can help accomplish goals. By transmitting data at 10Gbit/s, 40Gbit/s, 100Gbit/s or 12940Gbit/s, they can ensure that data arrives quickly. Transceiver modules that are capable of handling fast speeds can help with downloads and high and low bandwidth video transmission.

Transceiver modules are instrumental in ensuring that the data is transmitted securely, expeditiously, and accurately across the media. Choosing the right type of transceiver for your network is not always easy, but knowing above discussed parameters beforehand helps you narrow it down to a few transceivers. FS.COM offers a sea of transceiver modules which are fully compatible with major brands, like the above mentioned MGBSX1 and MGBLX1, the Cisco compatible transceiver modules.