With growing data traffic volume in recent years, the existing 10Gb/s optical networks are becoming saturated, which drive the great need for 40G and 100G networks. In turn, 100G network also can bring benefits for network operators. For example, 100G network can reduce the cost per bit, improve the utilization of existing fiber and reduce the network delay. This post intends to explore the options to get 100G connection.

As we all know, existing 10G network use two fibers in either a SC duplex or a LC duplex connector to realize data transmission. But different from this transmit type, data in 100G network often get multiplexed and transferred over the 4 or 10 parallel wavelengths on a single fiber, which means the lanes of the two kinds of networks are a little different. This is one problem that should be considered when deploy 100G connections.

Except for that, the cost is another problem needed to be resolved. No matter the 40G or 100G, both of them require more fibers and optical connectors, resulting in increasing cost. For example, 40G Ethernet and 100G Ethernet over multimode fiber uses parallel optics at 10 Gb/s per lane. One lane uses one fiber for each direction of transmission. So 40G Ethernet requires eight fibers. And 100G Ethernet requires 20 fibers.

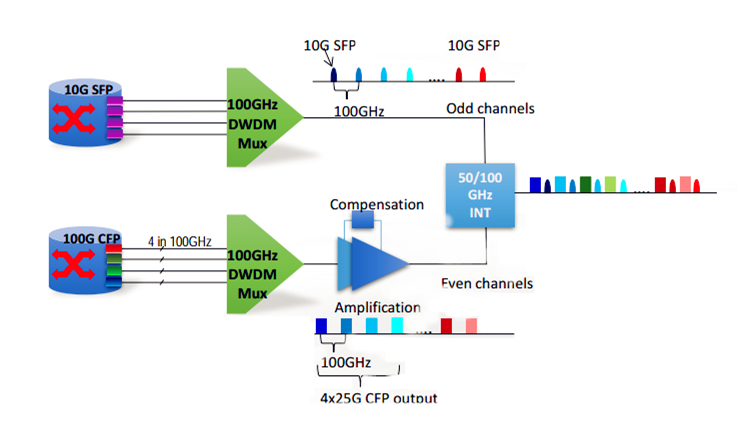

With the boom application of cloud services, telemedicine, video on demand, etc, data rate migration encompassing the entire optical network. Therefore, some core networks have deployed DWDM to release this bandwidth explosion. With large capacity transmission ability, DWDM technology offers a cost-effective method to meet the bandwidth requirements.

In many cases, to avoid the high cost and save cost, some operators often use one DWDM Mux to add one or more 100G services into the same fiber. The picture is showing one of that cases. In this case, 10G and 100G services are multiplexed by two separated 100GHz DWDM MUX. Owing to the 100G services are easy to be affected by dispersion, so the optical amplifier and DCM (Dispersion Compensation Module) are added in the links to boost the signal power. Then the 10G and 100G services are bundled together by using the interleaver which is an optical router often used in DWDM system. And finally the 100G connection is achieved.

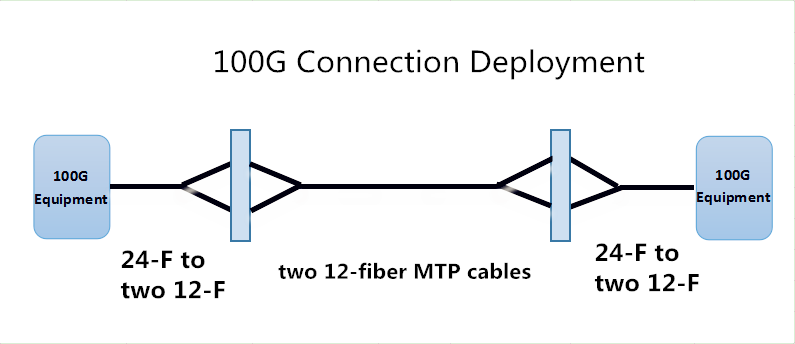

Nowadays there are various products on the market to support 100G connections. The most often used is 100G CFP, 100G QSFP28 and MTP optical cables. For many network operators, the option one that uses 100GHz DWDM Mux, optical amplifier, DCM and 100G optical transceivers maybe a little expensive. However, except for using DWDM Mux to achieve 100G connections, there is another choice. It is to achieve 100G connections with MTP assemblies.

In this connection, the 100G connection can be realized by using a MTP cord with a 24-fiber MTP connector on one end and two 12-fiber MTP connectors on the other end.

Notes: this simple chart just illustrates a short distance 100G connection.

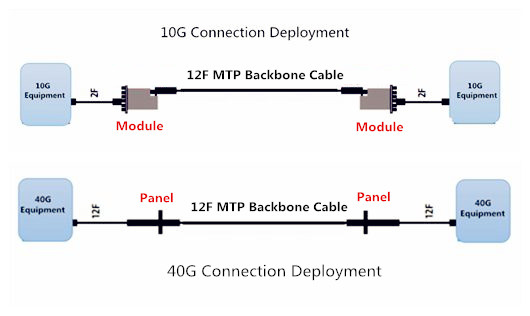

Besides, since 10G connections usually use common fiber optic cables with LC or SC connectors, and the 40G connections use 12-fiber MTP cables, while 100G connections utilize 24-fiber MTP connections. Therefore, migrating from 10G/40G to 100G can be realized. Look at the basic 10G and 40G deployment scenario.

From the picture we can see, the similarities of these connections are that they are using MTP cables. Just change the cable types and then migrating from 10G to 40G and 100G are possible.

100G connection is the trend in the future data centers. This post introduces two options to achieve 100G connections with existing optical components. According to different requirements, you can choose a suitable solution. FS.COM supplies various optical components to meet diverse applications in data centers and enterprise networks. If you want to know more details about 100G networks, please visit our website www.fs.com.